Flexography is a popular printing process that uses flexible relief plates for printing on a variety of materials, from paper and plastic to metallic films. While the end results can be outstanding, achieving consistent high-quality prints requires a refined and streamlined plate-making process. Here are five effective strategies to smoothen your flexo plate making process.

Invest in High-Quality Raw Materials

Always opt for quality flexographic plates. The quality of the plate will directly influence the print’s clarity, ink transfer, and overall finish.

Utilize top-grade solvents for washing and post-processing. Low-quality solvents can leave residues or not clean the plate effectively, leading to printing inconsistencies.

Optimize Your Exposure Unit

Consistent exposure is crucial for plate development. Make sure your exposure unit has even light distribution, and regularly check for any worn-out bulbs or elements.

Properly calibrating the unit ensures that plates are exposed for the right amount of time. Too much or too little exposure can result in a plate that’s either too hard or too soft, both of which can adversely affect the print quality.

Maintain a Controlled Environment

Flexo plate making is sensitive to environmental factors. Maintaining a controlled environment ensures that external elements don’t interfere with the plate-making process. Keep the area free of dust and debris. Any contamination on the plate surface can cause defects in the printed image.

Control humidity and temperature. Fluctuations can affect plate quality, especially during drying.

Implement a Robust Quality Control System

Regularly inspect plates for defects before they’re used for printing. Look for issues like pinholes, incomplete washout, or underexposure. Employ magnification tools or microscopes for detailed inspections.

Consider a documentation system where you note down plate quality, issues observed, and any corrective actions taken. This can be invaluable for troubleshooting recurring problems.

Train and Retrain Your Team

A skilled team is essential for a streamlined flexo plate-making process. Ensure that all team members are adequately trained in every aspect of plate making, from material handling to machine operation.

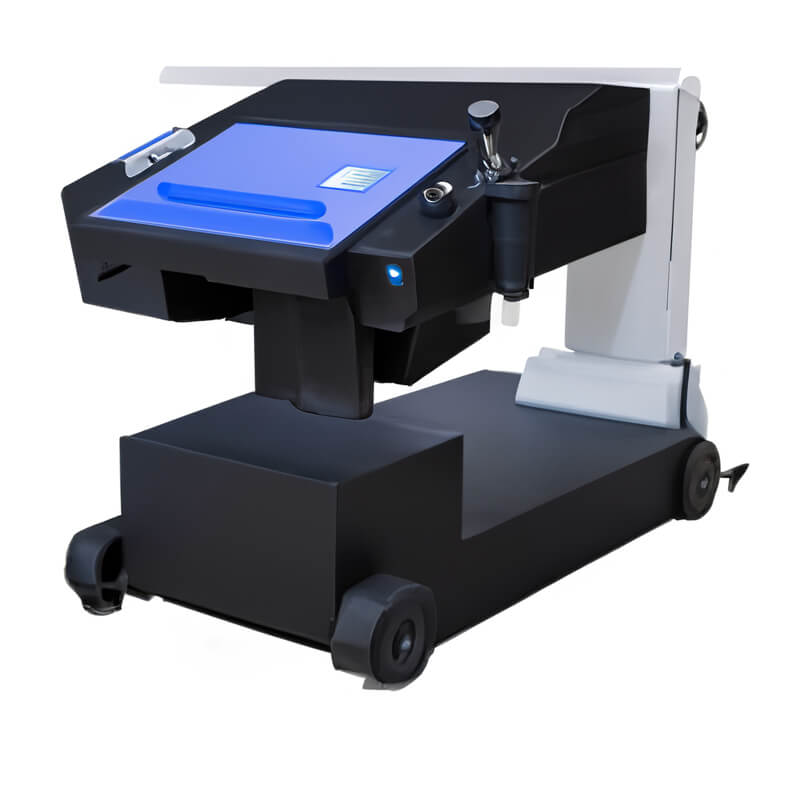

To learn more about the flexo plate making process, visit the website where you will also get a vast collection of plate makers.