Signs Your Photopolymer Plate Maker Needs Some Maintenance

There are many ways that you can tell that a photopolymer plate maker needs some maintenance. Unfortunately, some of the users do not pay attention to the signs that these machines produce to show the need for immediate maintenance.

There are many signs that you should watch out for when it comes to maintaining your photopolymer plate makers. In this article, we have shared some of the most common signs that most people ignore. They include:

Noise When Operating

Like most of the machines in the market, photopolymer plate makers are designed to operate smoothly and quietly. The only noise that should be coming from these machines when operating is motor movements, and it is usually very small. In fact, it is difficult to identify this noise. But when you start hearing other noises coming from the machine, you need to pay a lot of attention. Maintenance might be required.

Over Heating

photopolymer plate makers are designed with cooling systems that deal with the heat produced when operating. In most cases, the fans are the ones that do this. In fact, the cooling system is usually the one that produces noises from these machines. If the cooling system breaks down, then the machine will immediately start overheating. It means maintenance is necessary.

Spike In Power Consumption

The power consumption for photopolymer plate makers might increase as the machine ages, but it is usually at a very low rate. If you notice the machine has all of a sudden posted a spike in its power consumption, then there is a possibility that a fault. So spike in power consumption is a sign that you need to maintain your machine.

Downgrading Engraving Quality

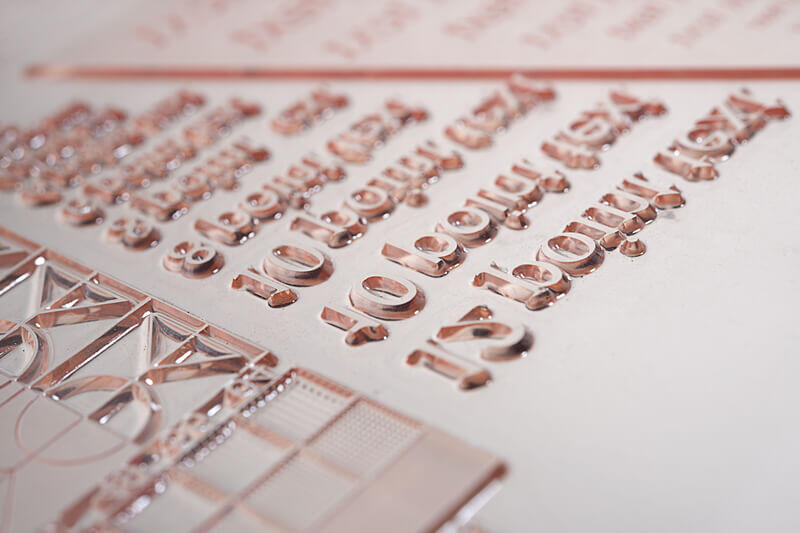

Has the photopolymer plate maker shown a decline in the quality of the engraving? Well, this is another sign of something wrong with the machine. In most cases, the engraving system of the photopolymer plate maker might be the problem. However, many things can cause this deterioration in quality

For more about the photopolymer plate makers, go here. The manufacturer has a range of options for you.